PCB assembly (PCBA) Optical Inspection (AOI) Machine Programming Software

Download Software

(The trial software is free. Start using the fully licensed software for as little as $600.

For over 40 years, Unisoft has had the best prices.)

Fully functional trial licenses,

available at no charge, are normally provided for approximately one month to

allow you to try out the software. Let us know if you're interested.

Automatic Optical Inspection (AOI) Equipment Programming Software

Click here for software download & more information!

"Work is the refuge of people who have nothing better to do."

Do you dislike spending endless hours programming your PCB inspection AOI machines? You'll have more time to pursue your interests and passions thanks to the Unisoft ProntoAOI software that we've been developing for over 40 years. Consider how much time you could have added to your day for reading, playing games, or simply just unwinding. All in good fun, big boss, about these.

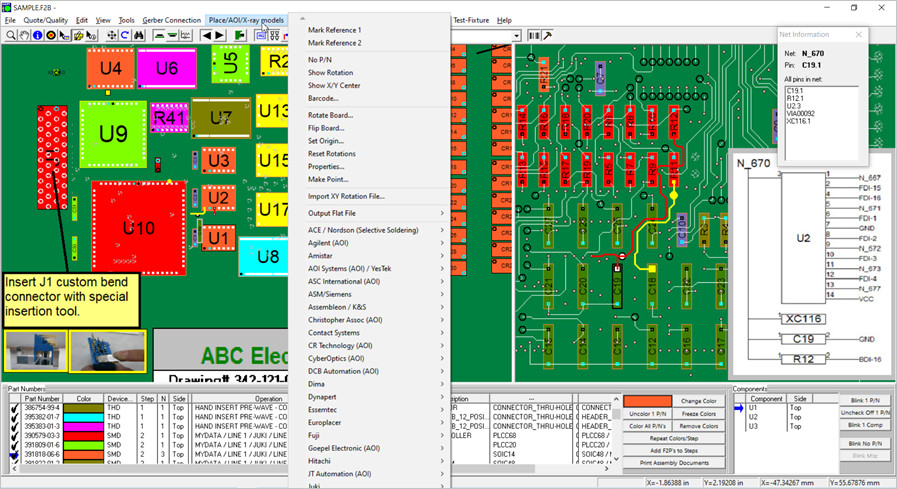

Seriously, the Unisoft ProntoAOI software will do the job of programming your

AOI machine quickly. ProntoAOI is used by electronic manufacturers to quickly

program their Automatic Optical Inspection (AOI) machines & includes the basic

features of ProntoVIEW-MARKUP. The ProntoAOI software

translates CAD or Gerber and Bill of Materials (BOM) files into real reference

designators, X/Y body centers, Theta rotation, part numbers, etc. and this data

is then used by Process Engineers to program their AOI machines. ProntoAOI

programs most popular AOI Equipment such as Agilent, Aleader, AOI Systems, ASC

International, Beijing Torch, Christopher Associates, CR Technology,

CyberOptics, DCB Automation, Goepel Electronics, JT Automation, Jutze

Technology, Koh Young, Landrex Technologies, Machine Vision Products (MVP),

Marantz, MEK, Mirtec, Omron, Orbotech, Parmi, Pemtron, Photon Dynamics, Saki,

Samsung, Shanghai Holly, Test Research, Vi Technology, Viscom, ViTrox, YESTech,

YesTek, ZhenHuaXing, etc. Further the Unisoft software as options

available to input one type of CAD file format and then export a standard CAD

file format such as GENCAD, IPCD356, IPC-2581, MENTOR Neutral, PADS, Fabmaster,

.XML, etc. that can then be used to program those AOI machines.

Trial Software

(The trial software is free. Start using the fully licensed software for as little as $600.

For over 40 years, Unisoft has had the best prices.)

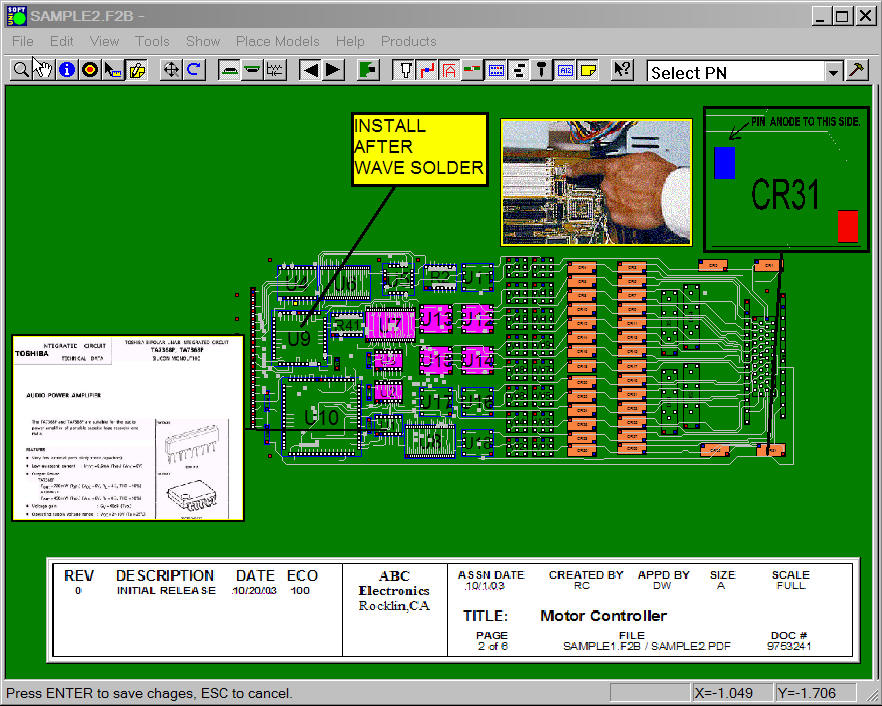

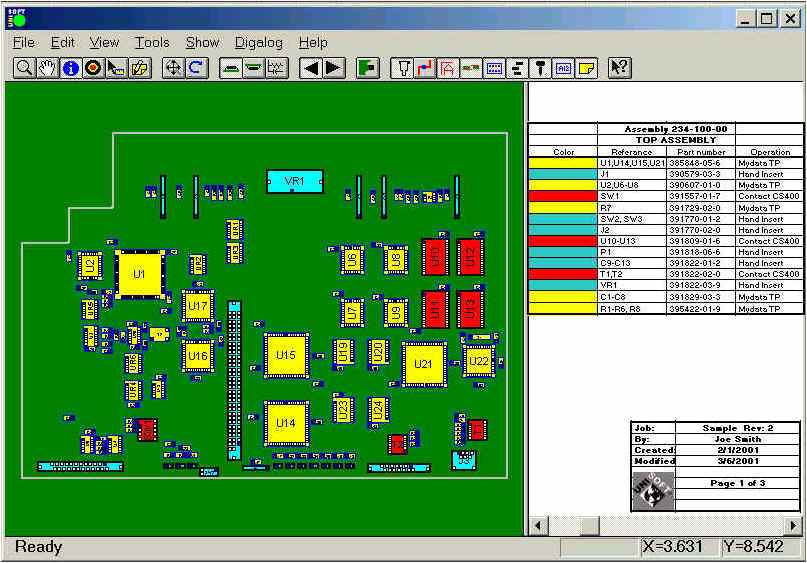

ProntoAOI also comes with the basic features of ProntoVIEW-MARKUP at no extra cost and is utilized by electronic manufacturers involved in PCB assembly. The software facilitates detailed viewing of PC board assemblies and enables the creation of necessary documents required during the PCB assembly. ProntoAOI enhances efficiency, communication, and minimizes errors throughout the production floor. Boasting over 100 features, ProntoVIEW-MARKUP supports every department involved in the daily operations of PCB assembly (PCBA) manufacturers. The software is utilized by management, assembly, inspection, design, test, troubleshooting technicians, and other personnel. The software creates assembly instructions that use unique colors for each part number and step in the assembly process, alongside generating matching kitting labels. It can locate any component, pin or part number, netlist, and finds shorts between traces, and provides a paperless hyperlinked schematic linked to the assembly. Annotation notes and graphics can be added to the display. The software enables fast PC Board first article inspection and general inspection. The software also generates reports that contain device and package type counts alongside quotation and cost estimations. With a current license, the Unisoft PC Board viewer software can be distributed to your production floor, vendors, customers, and others to aid assembly, first article inspection, general inspection, repair/rework, technician debug, and better communications. If necessary, ProntoVIEW-MARKUP can be remotely controlled from your application or equipment via the supplied external API programming interface.

Sample AOI machine setup file created by Unisoft ProntoAOI (all popular machine formats supported):

YESTECH AOI: .YESTECH_CAD [Header] Version= 1 RecipeName= 7807_TOP Scale= 25.4 InvertXPos= 0 InvertYPos= 0 RotationDir= 1 RotationOffset=0 BoardWidth= 9187.0 BoardHeight= 6364.0 PNLib= IsSharedPNLib= 0 PkgLib= PkgNameMap= IsTopSide= 1 [PartList] RefID NAME X Y Rot Pkg Description C144 315-507000-107 5150.00 3048.00 90 S6032T_TOP CAP: TANT 100uF 6.3V 20% CASE 6032 C77 315-406000-047 5871.50 2109.00 0 S3528T_TOP CAP: TANTALUM CHIP 4.7uF 20% 16V EIA 3528 C1121 315-304006-104 1779.00 700.00 90 S0402T_TOP CAP .1uF 16V Y5V 0402 C1055 315-406000-047 5127.00 693.50 90 S3528T_TOP CAP: TANTALUM CHIP 4.7uF 20% 16V EIA 3528 R311 347-000064-536 5694.00 1293.00 270 S0603T_TOP RESISTOR: 53.6 OHM 1% 0603 R165 347-000080-332 3166.00 2688.00 270 S0402T_TOP RESISTOR: 33.2 OHM 1% 0402 MIRTEC AOI: [Fiducial] Fid1_X= 0 Fid1_Y= 0 Fid2_X= 0 Fid2_Y= 0 [Part Info] Coordinate Transform=NO Part Count=82 #00000001,-53340,11430,342,385848-05-6,CR24,2-PIN THUR-HOLE / UNIVERSAL VCD AUTO INSERT #00000002,-37465,34925,342,385848-05-6,CR13,2-PIN THUR-HOLE / UNIVERSAL VCD AUTO INSERT #00000003,6985,57785,161,385848-05-6,CR1,2-PIN THUR-HOLE / UNIVERSAL VCD AUTO INSERT #00000004,-121920,17145,270,391777-06-8,C2,1206 / CHIP SHOOTER AUTO INSERT C211 003-W2122104K 5315 4360 0 0402 CAP .1UF 10V CERAMIC 0402 C194 003-W212A104K 567 5 3955 0 0402 CAP .1UF 10V CERAMIC 0402 C125 600-RW1120JW 6145 1575 180 0603 CAP RF 12 PF 600 SERIES C116 007-1213H473K 5625 1410 90 0603 CAP .047UF 50V CERAMIC 0603 C117 003-0012A104K 8300 1215 0 0402 CAP .1UF 10V CERAMIC 0402 C148 120-77131H121J 5625 2660 90 0603 CAP CERAMIC 120PF 50V 0603 SMD Part Count=82 #00000001=-869950,539750,180,395422-01-9,U11,SOIC8,I/O CONTROLLER #00000002=-1155700,273050,90,391818-06-6,U3,SOIC48,74HC14 #00000003=-869950,406400,180,395422-01-9,U12,SOIC8,ILD251 #00000004=-1447800,520700,90,391829-03-3,U4,SOIC20W,74HCT640 <xml version="1.0"> <unisoft version="1.0" units="mils"> <board name="C:\PROGRAM FILES\UNISOFT\SAMPLE.CAD" width="6910" height="2575"> </board> <layers> <layer name="TOP" top="true" bottom="false" sequence="1"/> <layer name="4" top="false" bottom="false" sequence="2"/> <layer name="5" top="false" bottom="false" sequence="3"/> <layer name="BOTTOM" top="false" bottom="true" sequence="4"/> </layers> <nets> <net name="BUFCLK"/> <net name="IOMCLK"/> <net name="IDI-16"/> </component> <component name="R36" x="-3800" y="550" devicetype="SMD" partno="391729-02-0" layer="BOTTOM"> <outline> <line x1="-3831" y1="651" x2="-3769" y2="651"/> <line x1="-3769" y1="651" x2="-3769" y2="449"/> <line x1="-3769" y1="449" x2="-3831" y2="449"/> <line x1="-3831" y1="449" x2="-3831" y2="651"/> </outline> <pins> <pin name="1" x="-2250" y="500" component="CR24" net="N_867" pin1="true"/> <pin name="2" x="-1950" y="400" component="CR24" net="CGND"/> <pin name="1" x="-1625" y="1425" component="CR13" net="N_829" pin1="true"/> <pin name="2" x="-1325" y="1325" component="CR13" net="N_871"/> <traces> <trace x1="-4575" y1="2000" x2="-4600" y2="1975" net="-RDLTCH" layer="BOTTOM"/> <trace x1="-4600" y1="1975" x2="-4600" y2="1950" net="-RDLTCH" layer="BOTTOM"/> <trace x1="-5475" y1="1025" x2="-5475" y2="1100" net="-IOMRD" layer="BOTTOM"/> <trace x1="-5725" y1="1575" x2="-5725" y2="1625" net="BUFCLK" layer="BOTTOM"/>

Online demonstrations, training and inquiries.

To start or schedule a meeting Click Here or call us at (enable JavaScript for our phone number) or email (enable JavaScript for our email addressindex.htm).

In our meeting, we can follow any direction you prefer, for instance:

-- Talk about your requirements, software inquiries, and other concerns.

-- Software demonstrations & training. We have the option to process one of your PC Boards or demonstrate the software using our own data files.

-- Provide you with a fully functional trial version of the software license.

-- etc.

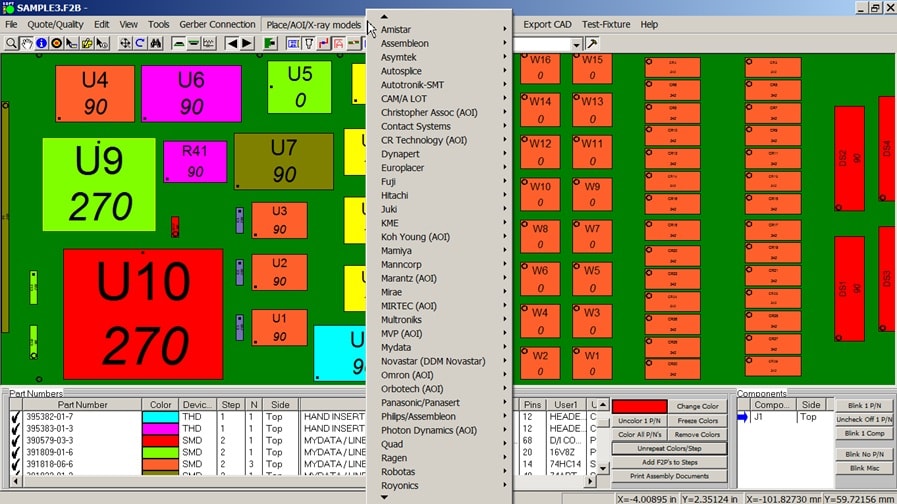

Some features of ProntoAOI:

- 5 minutes to program your PCB assembly ( PCBA ) AOI machine

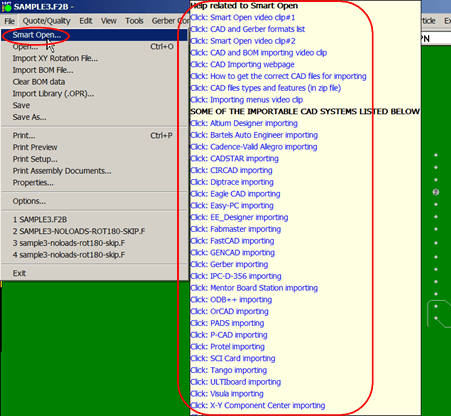

- Step 1 - Choose the XY data you wish to use such as either the full CAD file, XY Rotation file or Gerber only file and import that data into the Unisoft software.

- Step 2 - Import the BOM

- Step 3 - Set the REFERENCE 1 and 2 points.

- Step 4 - Set your 0,0 XY origin. This is an optional step.

- Step 5 - Generate the AOI machine file.

- Saves assembly machine run time by off-line creating and verifying of assembly programs

- Automatically create assembly machine programming files from all types of CAD, Gerber, XY rotation, BOM, etc. data file formats

- BOM crosscheck and clean up (DNI check, duplicate component part numbers, etc.)

- BOM comparision

- Panelization option for machine export

- 8 options to create and assign fiducial lineup reference points

- Rotation reset option to IPC-7351B Level A zero degrees component rotation standard, rotation modification by part number and other rotation modification options

- Via either library import or manually user can add part libraries, package shapes, assembly information notes, etc.

- Include/exclude components by part number option on machine export

- Multiple machine output format options

- Options are available to export a standard CAD file format such as GENCAD, IPCD356, IPC-2581, etc. that can then be used to program the AOI machine.

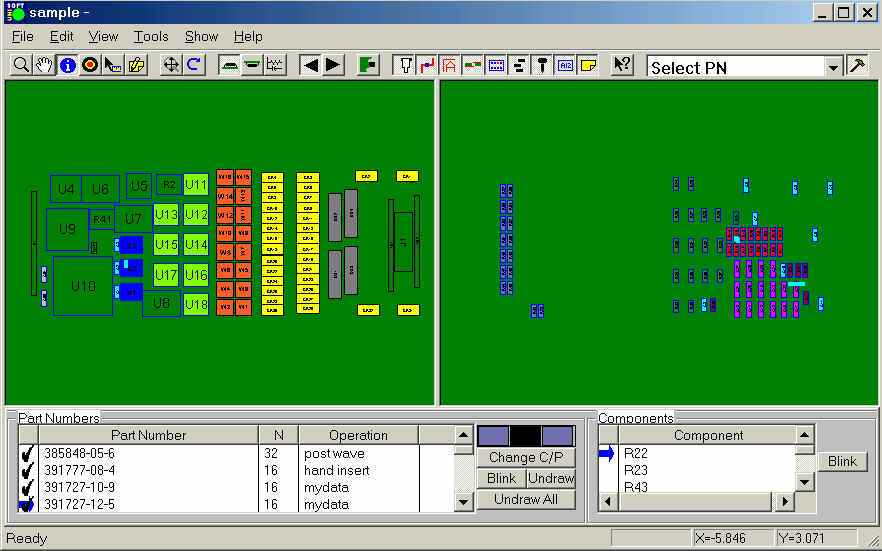

The ProntoAOI software also includes the basic features of ProntoVIEW-MARKUP:

- Over 100 features to aid every department every day on the shop floor of PCB assembly ( PCBA ) manufacturers. Used by management, assembly, inspection, design, Test, troubleshooting technicians, etc.

- Imports all types of CAD, Gerber, XY rotation, BOM, etc. data formats

- API - Remote application programming interface (API)

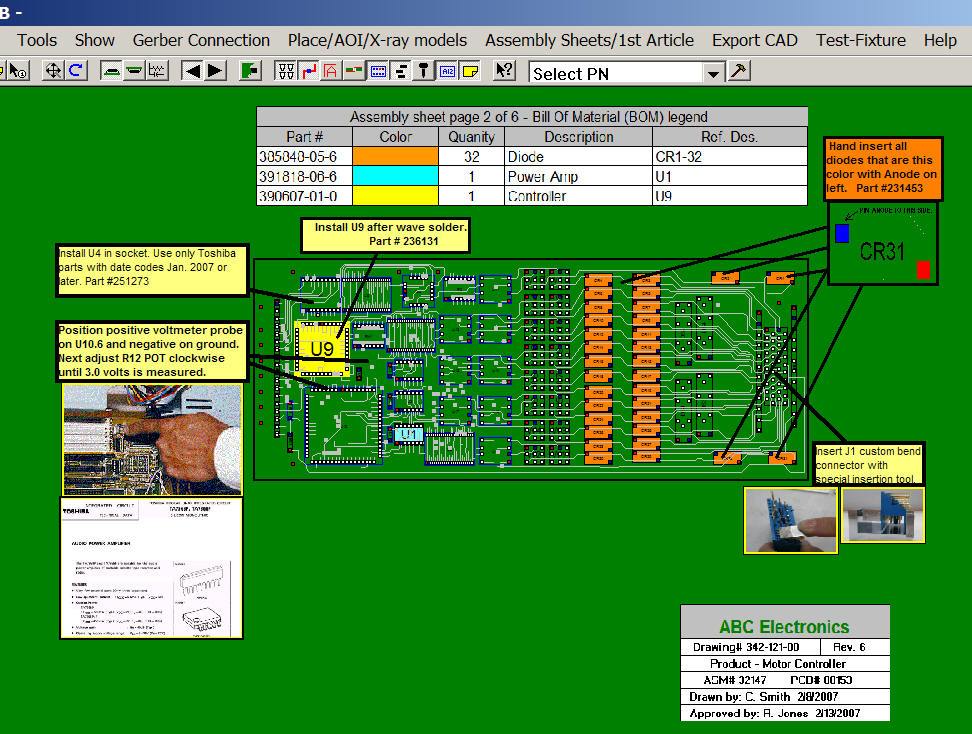

- Assembly - Assembly and Inspection Documents

- Assembly - Create assembly process Kitting Labels

- Assembly - Create assembly process documents - single and multiple pages per step with unique color per step

- Assembly - Insert PCB assembly ( PCBA ) gerber, photos, etc. to enhance background display

- Assembly - Overlay gerber, graphics, etc. for PCB assembly ( PCBA ) details

- BOM - Cross-Checking the BOM

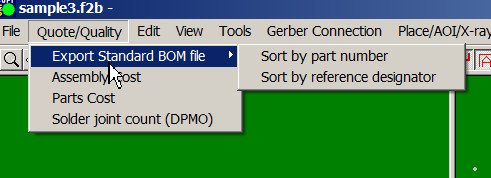

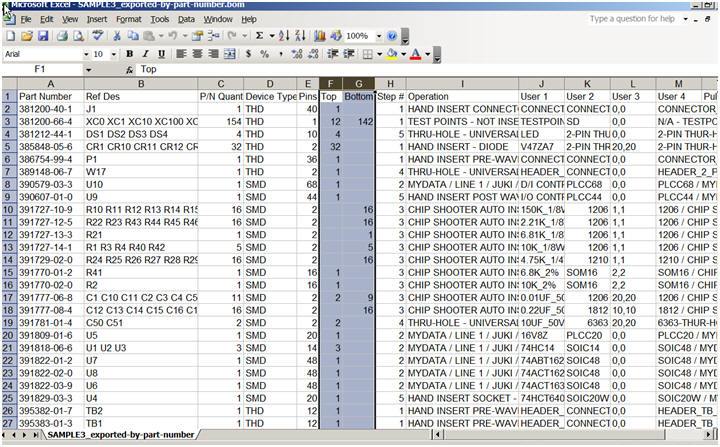

- BOM - Export standardized BOM files to Part Sourcing, MRP and ERP software

- BOM - Edit BOM information

- BOM - Importing any format of BOM in text, Excel and PDF files

- BOM - BOM files comparison

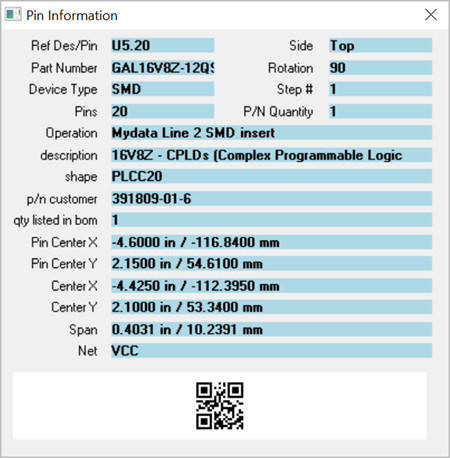

- Inspection - Component pins displayed turned on or off by part number

- Inspection - Cross-Checking the BOM

- Inspection - Crosschecking PCB assembly ( PCBA ) component footprint and BOM footprint

- Inspection - First Article Inspection (blink and check off by part number)

- Inspection - Identify, color and blink Do Not Install (DNI) components

- Inspection - Polarized component inspection, assembly, etc. via pins turned on/off by p/n, etc.

- Library - Library operation notes from part libraries, package, assembly information, etc.

- Menus - Customize the Menus and Splash Page

- Quote & Quality - Assembly Cost by Component Span Report for Quoting

- Quote & Quality - Assembly or Parts Cost by Part Number Report

- Quote & Quality - Cycle Times - calculate component assembly cycle times (Takt time)

- Quote & Quality - Electronic Components Search (Digikey, FindChips, Octopart, etc.)

- Quote & Quality - Solder Joint Count - Defect Per Million Operations (DPMO) Report

- Technician Troubleshooting - Find components, aid inspection, debug, rework, etc.

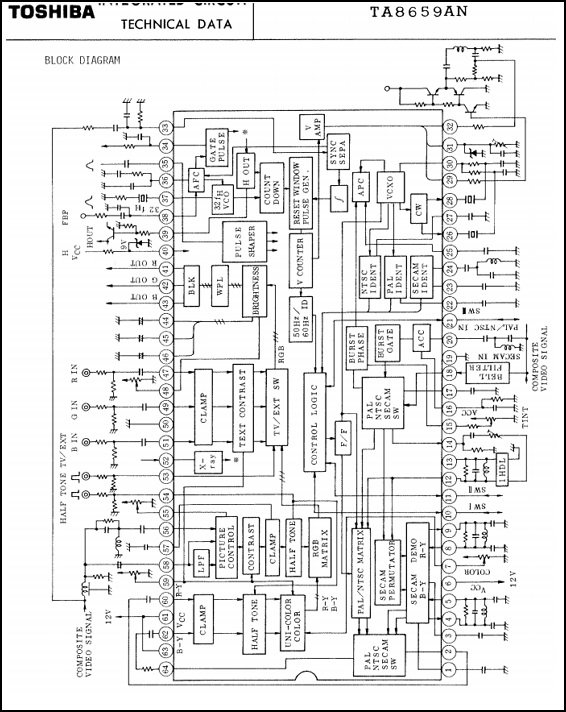

- Technician Troubleshooting - Hyper-linked Schematic & Assembly

- Technician Troubleshooting - Netlist, traces, schematic, pins, etc.

- Technician Troubleshooting - Find short between 2 trace runs

- Test - Test probe mapping, DFT, etc.

- Test - Netlists from only gerber data

- Viewer - Unisoft PCB assembly ( PCBA ) viewer distribution

- Quick Return On Investment (ROI). All processes faster and more accurate

Other features in the Unisoft software suite:

- AOI machine programming wide support. For example: YESTech, Mirtec, Orbotech, Agilent, Omron, AOI Systems, CyberOptics, MVP, Koh Young, ViTechnology, etc.

- Assembly machine programming wide support. For example: Assembleon, Mycronic/Mydata, Juki, Siemens, Universal, Fuji, Samsung, Panasonic, etc.

- CAD translation - Export Output formats include GENCAD, Fabmaster, IPC-D-356, IPC-2581, Mentor Graphics, PADS .ASC, .XML, Unisoft .FBA, etc.

- Selective Soldering machine programming

- Test equipment programming - ATE In-circuit Bed Of Nail, MDA, Flying Probe testers, boundary scan, etc.

- CELLS Workflow MES - Manufacturing Execution System (MES) product and job tracking software module

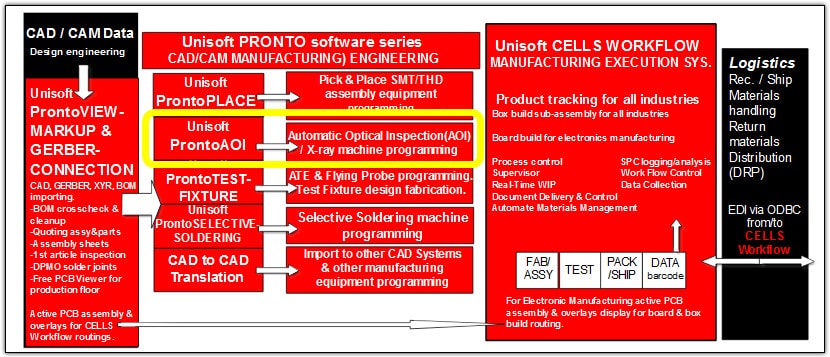

Unisoft ProntoAOI Software Overview Diagram

The trial software has HELP for most menu items by hovering over the menu item for a second then click any of the videos, manual or website links to learn about the software.

VIDEO: Click the video above for product overview.

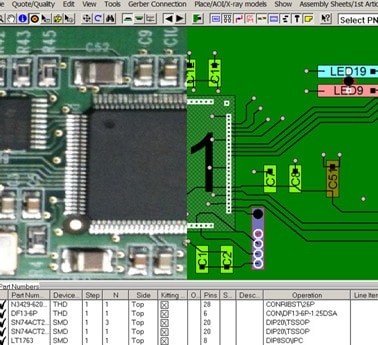

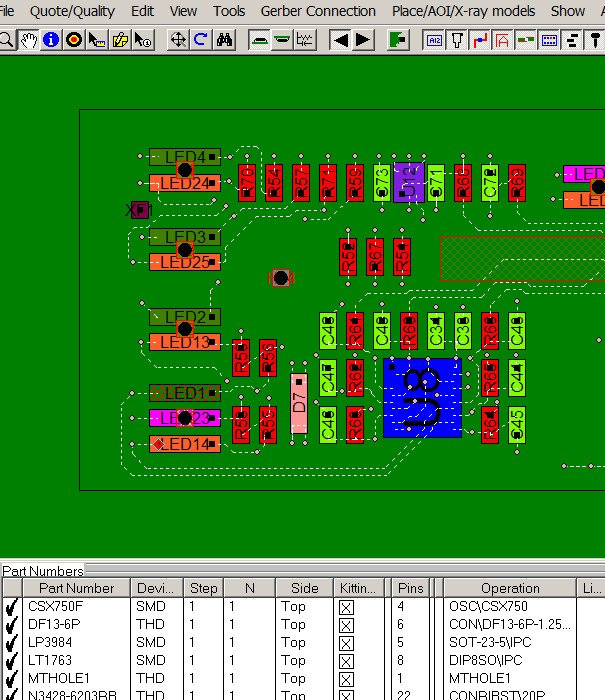

PCB assembly (PCBA) CAD Viewer &

Gerber Viewer Software

Please enter your email to receive your software and more information.

Unisoft over 40 years and 4000 customers.

Please double check that your email address is correct.

Email addresses are kept private.

The software download link, more information and periodic updates will be sent to this address.

Optionally to receive your software call us (enable JavaScript for our phone number).

ProntoVIEW-MARKUP

The basic features of ProntoVIEW-MARKUP are included at no additional charge and adds features such as detailed viewing of PC board assemblies and the creation of documents, etc. required throughout the PCB assembly ( PCBA ) process. The software increases efficiency, communications and reduces errors across the production floor. With over 100 features aids every department every day on the shop floor of PCB assembly ( PCBA ) manufacturers where it is used by management, assembly, inspection, design, Test, troubleshooting technicians and other personnel.

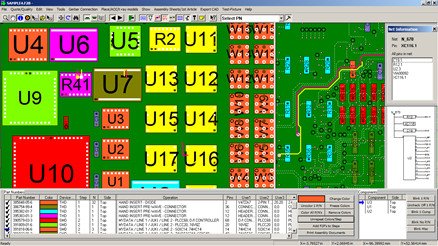

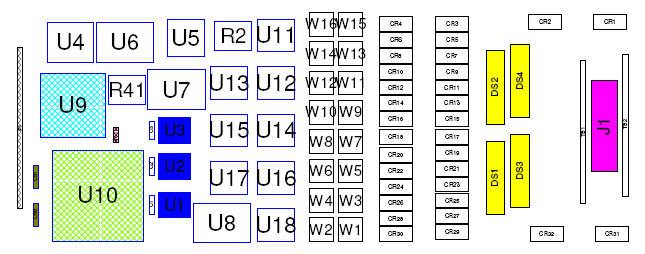

The information and figures that follow outline a few of the features of ProntoVIEW-MARKUP.

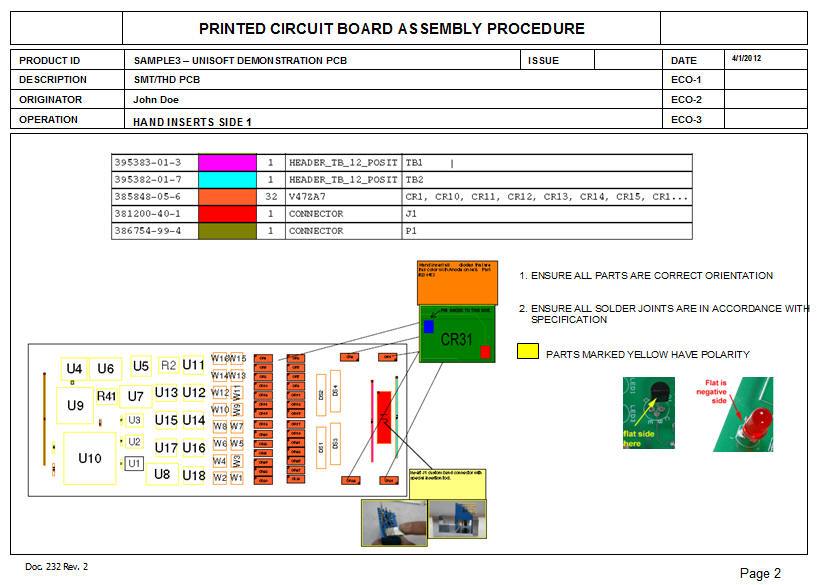

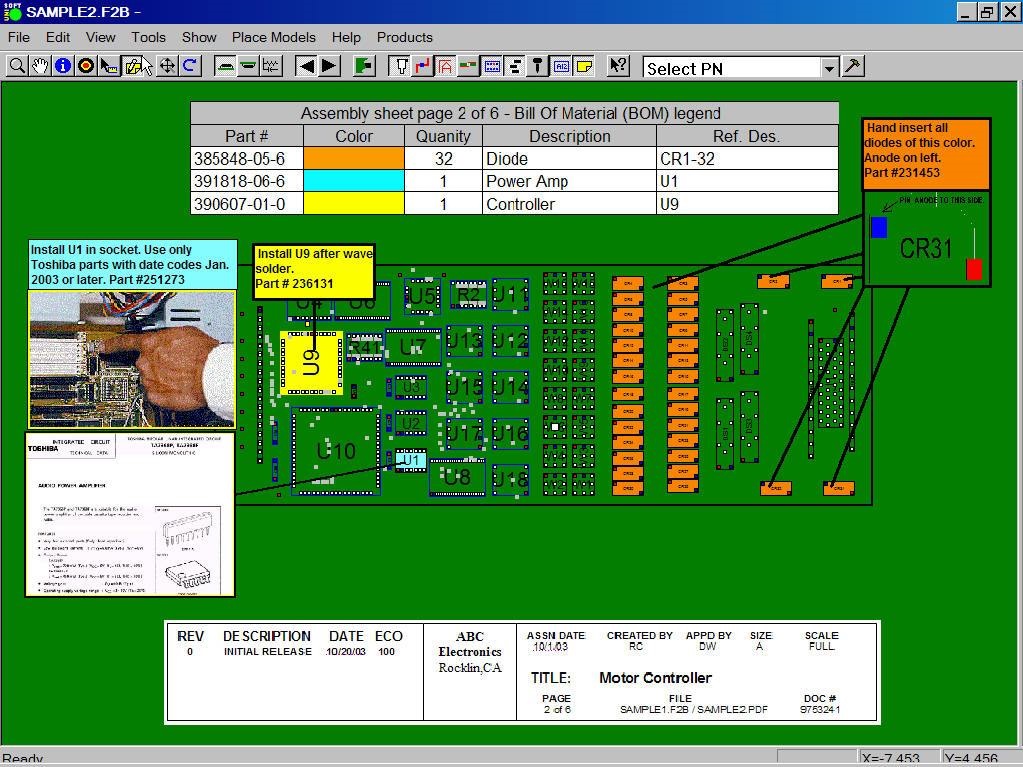

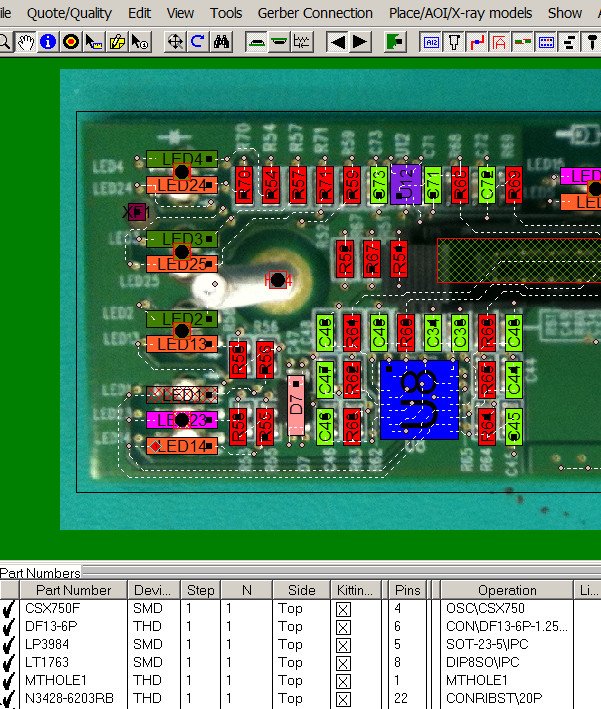

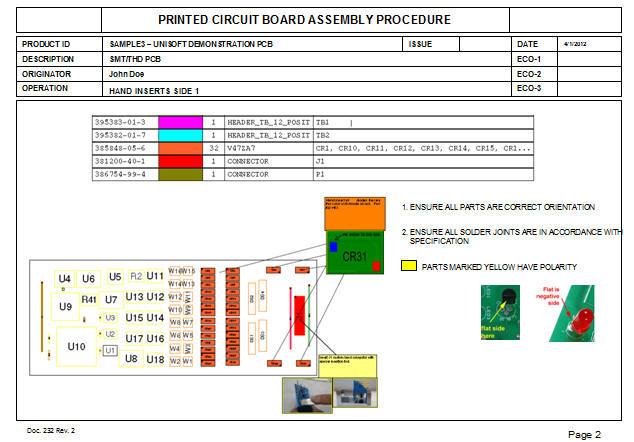

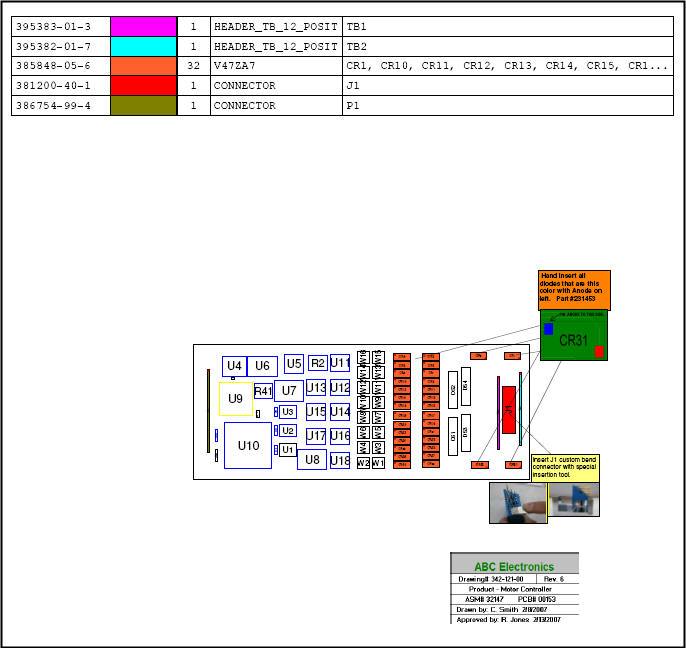

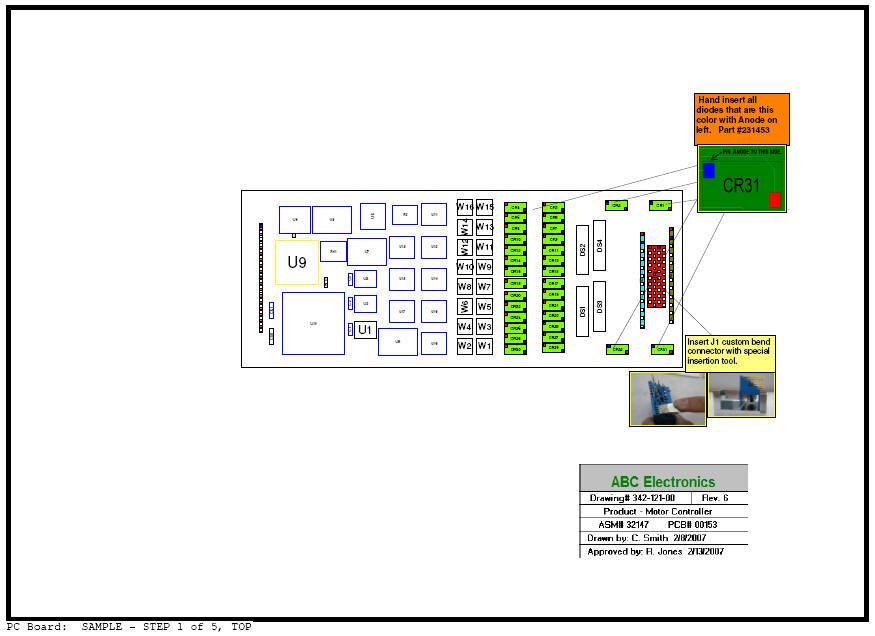

Assembly Process Documents

The Unisoft software allows you to quickly create matching assembly lists and assembly drawing sheets for each step in the assembly process. Part numbers are automatically assigned to the assembly step you wish (for example: Step 1 for Hand Inserts, Step 2 Chip Shooter components, etc). The part numbers are then automatically uniquely colored. If needed, overlay annotation notes can be added to each step. Next for each step matching assembly lists and assembly drawings are created. These drawings can either be printed or save to a file (PDF Adobe, etc.) or displayed on the screen.

Download a sample of process and assembly sheet documentation created by this software [PDF].

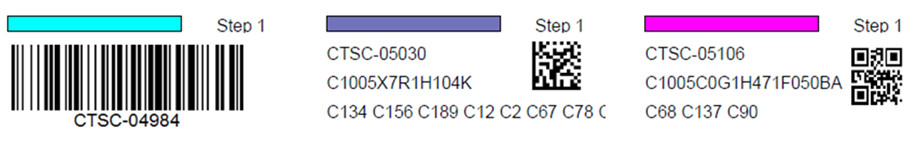

Kitting Labels

The Unisoft software allows you to quickly create Kitting Labels with barcodes for fast and accurate electronic component kitting. Quickly select the component part numbers for which you wish kitting labels created. Each label contains the part number, unique part number color, step number, p/n description, reference designator, etc. Fast and easy electronic kitting labels for kitting work orders.

Barcodes of various types can be printed on the kitting labels and shown on the display for quick kitting, fast assembly machine feeder loading, verification, inspection, etc.: 2d-qr code, 2d-data matrix, etc.

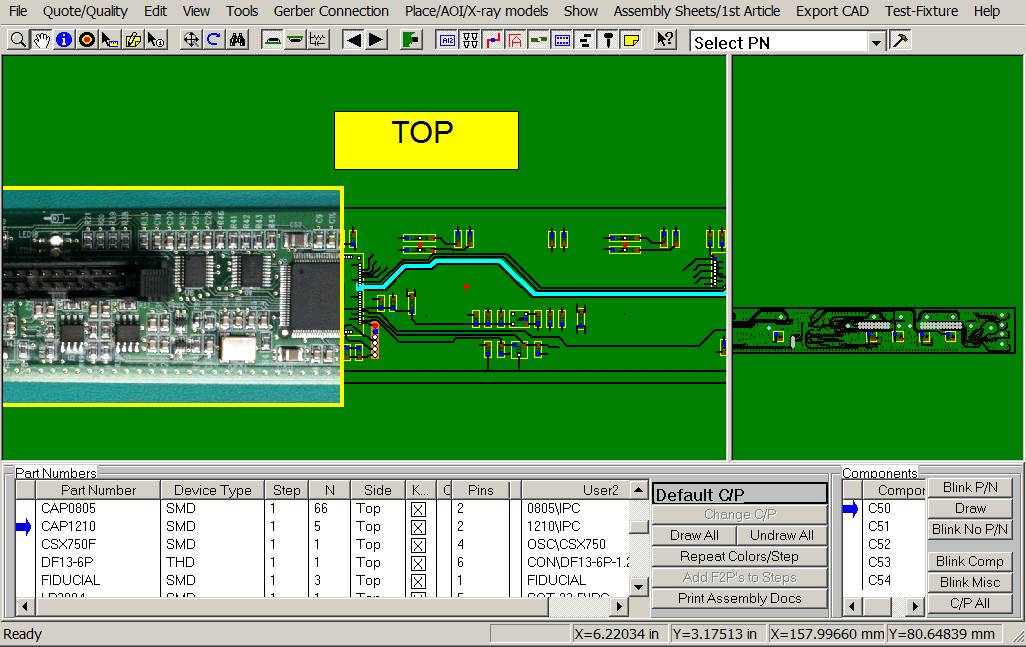

Paperless Assembly Instructions - use display only for slide line PCB assembly (PCBA), etc.

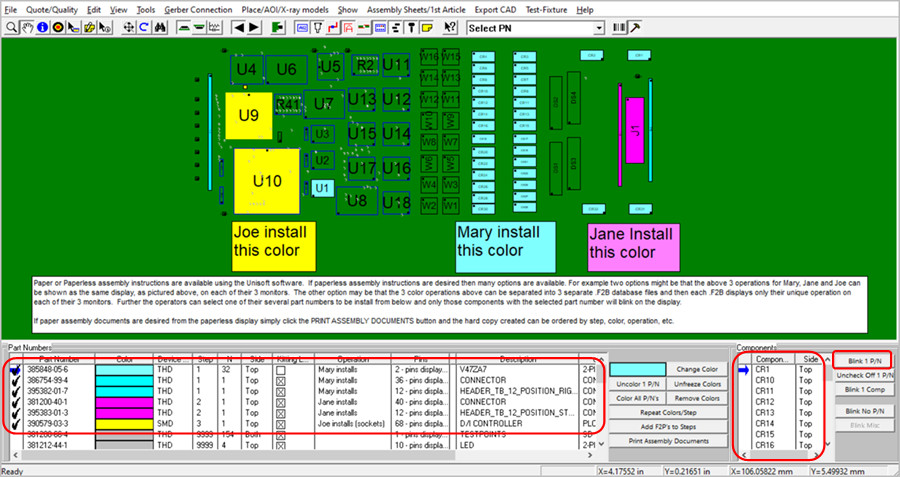

Paper or Paperless assembly instructions are available using the Unisoft software. If paperless assembly instructions are desired then many options are available. For example two options might be that the below 3 operations for Mary, Jane and Joe can be shown as the same display, as pictured above, on each of their 3 monitors. The other option may be that the 3 color operations above can be separated into 3 separate .F2B database files and then each .F2B displays only their unique operation on each of their 3 monitors.

Further the operators can select one of their several part numbers to be install from below and only those components with the selected part number will blink on the display.

If paper assembly documents are desired from the paperless display simply click the PRINT ASSEMBLY DOCUMENTS button and the hard copy created can be ordered by step, color, operation, etc.

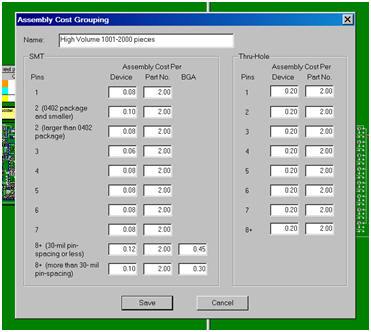

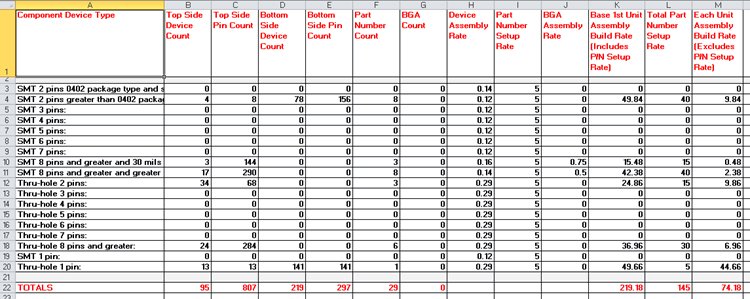

Quoting - PCB assembly (PCBA) Cost Estimate Report

Import your PC Board into the Unisoft manufacturing software and you instantly receive a report containing component counts for top and bottom of the PC Board broken down by SMT, Fine pitch, BGA's, Thru-hole, etc. with the cost for each group. You can create as many PCB assembly (PCBA) Cost templates as you wish, for example one each for either a Low, Medium or High volume build. This is a great quoting time saver for Contract and OEM manufacturers.

Example of a few lines of a report follows:

PC Board: 123-456

Date: 1-22-2013

Base 1st Unit Assembly Build Rate (Includes P/N Setup Rate) = 219.18

Each Unit Assembly Build Rate (Excludes P/N Setup Rate) = 74.18

Total Part Number Setup Rate = 145.00

________

SMT 2 pins greater than 0402 package type: Greater than .040 inch distance between pin 1 and 2.

Top - 4 = total device count, 8 = total pin count

Bottom - 78 = total device count, 156 = total pin count

Part #'s - 8 = total part numbers

Base Rate: 49.84 = (0.12 * device count) + (5.00 * part #'s)

SMT 8 pins and greater and 30 mils or less pin spacing (fine pitch):

Top - 3 = total device count, 144 = total pin count

Bottom - 0 = total device count, 0 = total pin count

Part #'s - 3 = total part numbers

BGA's - 0 = included in above count.

Base Rate: 15.48 = (0.16 * device count) + (5.00 * part #'s) + (0.75 * BGA count)

Component Part Cost Report

Instantly create a component part cost report. This report is used by Contract and OEM manufacturers to quickly estimate component parts costs. The report contains the total component part cost for the PC Board and breakdown by part number.

Report type: Parts count with quotation and cost estimation. PC Board: Controller Date: 1-12-09 Total parts cost = $43.31 ____

| 381200-40-1 | 1 | $0.23 | $0.23 |

| 381212-44-1 | 4 | $0.07 | $0.28 |

| 385848-05-6 | 32 | $0.45 | $14.40 |

| 386754-99-4 | 1 | $0.16 | $0.16 |

| 389148-06-7 | 1 | $0.06 | $0.06 |

| 390579-03-3 | 1 | $0.80 | $0.80 |

| 390607-01-0 | 1 | $0.65 | $0.65 |

| 391727-10-9 | 16 | $0.04 | $0.56 |

| 391727-12-5 | 16 | $0.04 | $0.64 |

Solder Joint Count - Defect Per Million Operations (DPMO) Report

Instantly create a report of the total solder joint count for Defect Per Million Operations (DPMO). This report is used by Contract and OEM manufacturers for quality tracking. The report contains the total solder joints for the PC Board broken down by SMT and Thru Hole and part number.

Report type: Solder joint count with quotation and DPMO estimation.

PC Board: Controller

Date: 1-12-09

Total Solder Joints = 1104

Total SMT Solder Joints = 598

Total Thru Hole Solder Joints = 506

____

SMT 2 pins greater than 0402 package type: Greater than .040 inch distance between pin 1 and 2.

Top - 4 = total device count, 8 = total pin count

Bottom - 78 = total device count, 156 = total pin count

Part #'s - 8 = total part numbers

SMT 8 pins and greater and greater than 30 mils pin spacing:

Top - 17 = total device count, 290 = total pin count

Bottom - 0 = total device count, 0 = total pin count

Part #'s - 8 = total part numbers

BGA's - 0 = included in above count.

Thru-hole 2 pins:

Top - 34 = total device count, 68 = total pin count

Bottom - 0 = total device count, 0 = total pin count

Part #'s - 3 = total part numbers

Thru-hole 8 pins and greater:

Top - 24 = total device count, 284 = total pin count

Bottom - 0 = total device count, 0 = total pin count

Part #'s - 6 = total part numbers

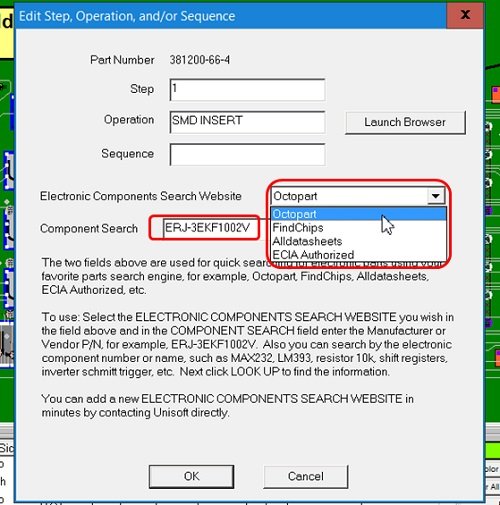

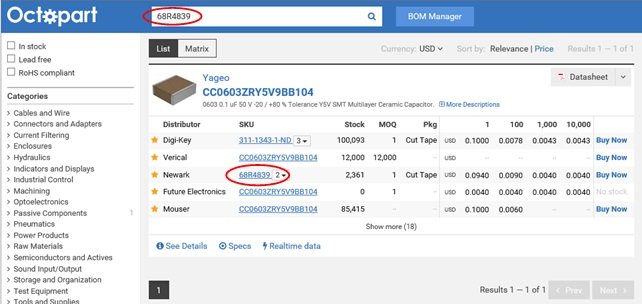

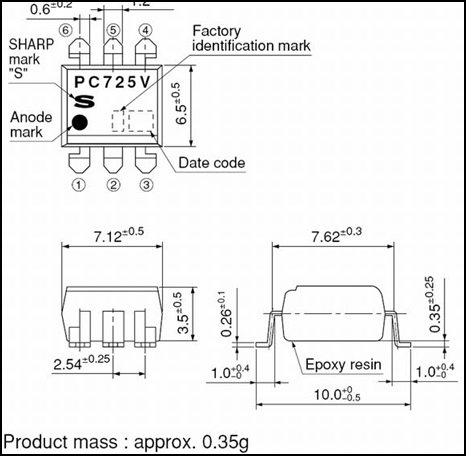

Electronic Components Search

The Electronic Components Search feature helps you find information such as cost, availability, part shape, electrical specifications, etc. Provides fast searching for electronic parts using your favorite parts search engine for example Octopart, FindChips, Alldatasheets, ECIA Authorized, etc.

Search for electronic parts using the Manufacturer or Vendor P/N for example ERJ-3EKF1002V. Also search by the electronic component number or name such as MAX232, LM393, resistor 10k, shift registers, inverter schmitt trigger, etc.

Export standardized BOM files to Part Sourcing, MRP and ERP software

All types of Bill of Material (BOM) formats can be imported into the Unisoft software and then exported to normalized standard BOM formats that can then be utilized by your other manufacturing software systems such as Part Sourcing, MRP, ERP, etc.

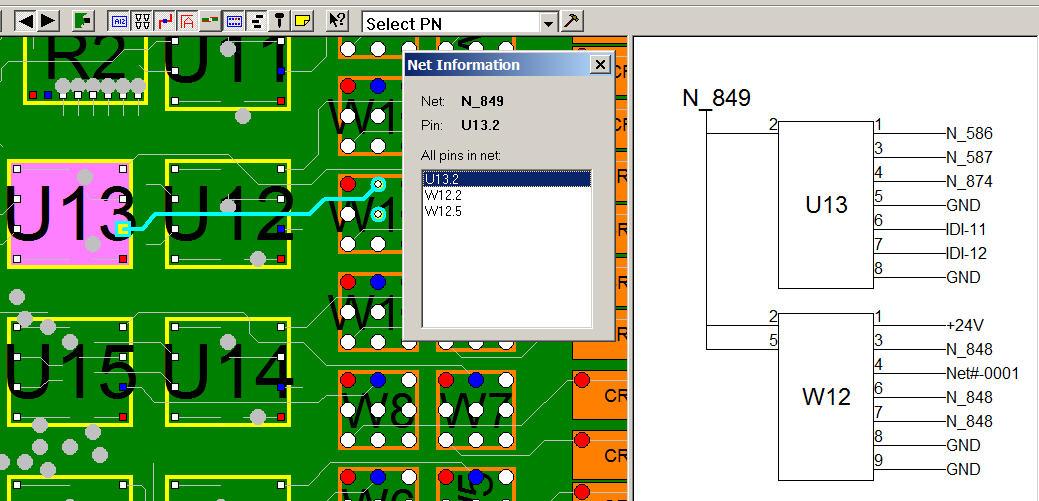

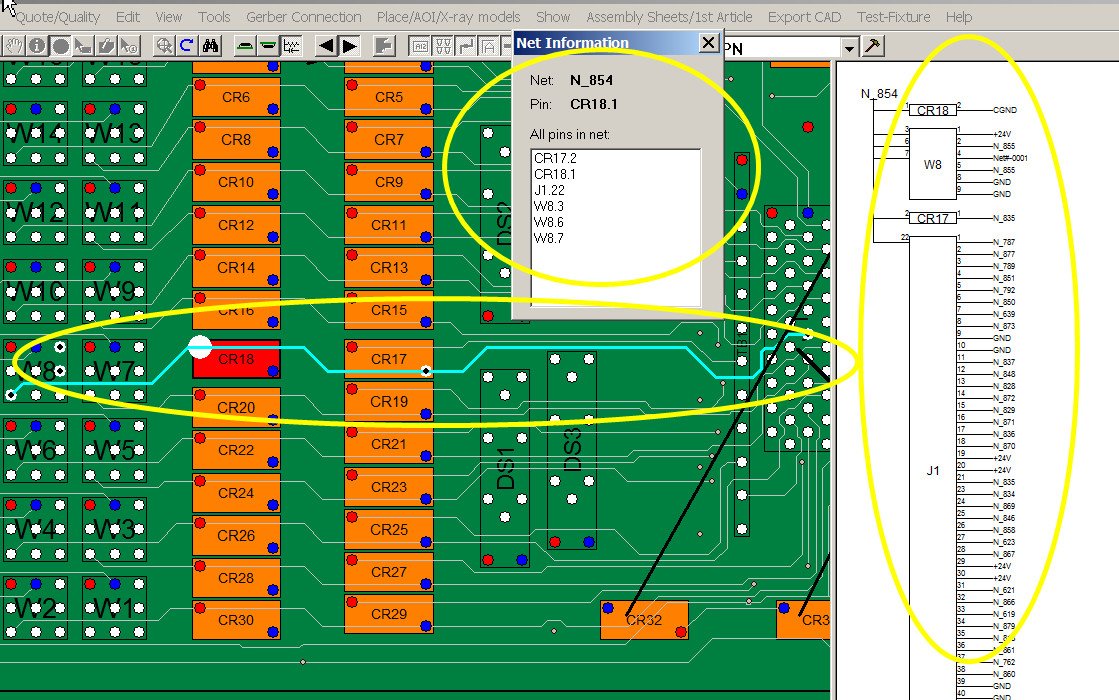

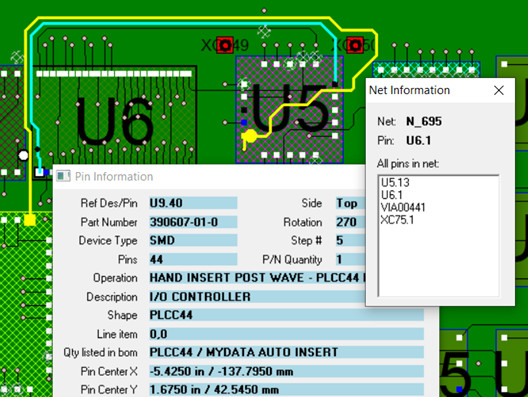

NETLIST window and blinking of all pins on the selected net

Easier drill down to component pins, trace runs and schematic. Display NETLISTS quickly using the "NET INFORMATION" window that displays the NET NAME of the selected component and pin and all the other pins on the net. The trace run of the selected net is highlighted and all pins on the net blink. If the schematic view is displayed then the net chosen is shown. The user can then select any one of the other pins on the net in the NET INFORMATION box. The result is the NET INFORMATION window will update to the new selected pin and the selected trace highlighted will update also. If the schematic view is displayed then that view will refresh too.

Find shorts between traces, netlists, netnames, component information, etc.

PC Board CAD Viewer & Gerber Viewer

The Unisoft software outputs a single board file of the PCB assembly ( PCBA ) that is compatible with the PCB assembly (PCBA) viewer. Customers with a current license can distribute the PCB assembly (PCBA) viewer and the Unisoft PCB assembly (PCBA) board file to your production floor, other divisions, vendors, customers, etc. to aid assembly, first article inspection, general inspection, repair/rework, technician debug, for enhanced communications, etc.